How does Automation Designing help to reduce millwork manufacturing costs? In the ever-evolving landscape of millwork manufacturing, staying competitive and efficient is crucial for businesses to thrive. One of the most promising advancements in the industry is the integration of automation designing and millwork drafting services. Automation has revolutionized traditional Millwork Drafting Services manufacturing processes, enabling businesses to optimize operations, reduce costs, and enhance overall productivity. In this blog, we will explore How does Automation Designing help to reduce millwork manufacturing costs?

Understand the Millwork Drafting Services

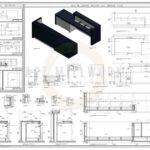

Millwork drafting services are essential for the construction and design industry. Drafting involves the creation of detailed plans for custom-made millwork items. These services encompass a wide range of architectural elements, such as cabinets, doors, moldings, and more, tailored to fit specific project requirements. The expert drafters utilize advanced software to produce accurate and comprehensive blueprints, ensuring seamless communication between architects, designers, and manufacturers. Precise millwork drafting streamlines the production process minimizes errors, and enhances project efficiency. This meticulous approach ultimately results in high-quality, aesthetically pleasing, and functional millwork installations that bring a sense of craftsmanship and uniqueness to any interior or exterior space.

After understanding the role of Millwork Drafting Services, let’s learn how Automation designing can significantly help to reduce millwork manufacturing costs while creating the Millwork Drawings. Here’s how it can be beneficial:

1. Efficiency and Accuracy

Automation in the drafting process allows for faster and more accurate design creation. CAD (Computer-Aided Design) software can generate precise 2D and 3D drawings , eliminating human errors and ensuring that the millwork components are designed correctly the first time. This reduces the need for revisions and the associated costs.

2. Material Optimization

With automated design tools, it becomes easier to optimize material usage. The software can identify the most efficient layout for cutting wood or other materials, reducing waste and saving on material costs.

3. Standardization

Automation allows for creating and using standardized design templates and components. This standardization streamlines the design process and ensures that the manufacturing process remains consistent, leading to cost savings and improved efficiency.

4. Time Savings

Automation can drastically reduce the time required for designing millwork components. Faster drafting means quicker production turnaround times, increasing productivity and cost-effectiveness.

5. Integration with Manufacturing Machinery

Advanced CAD software can integrate directly with computer numerical control (CNC) machines used in millwork manufacturing. This integration allows for direct translation of design data to the machines, reducing manual interventions and minimizing errors during production.

6. Minimizing Rework

Accurate and automated drafting reduces the chances of errors in design specifications. As a result, there are fewer chances of errors in the actual manufacturing process, leading to reduced rework costs.

7. Streamlined Communication

Automation facilitates seamless communication between designers, manufacturers, and clients. Everyone involved can access the digital designs, make real-time adjustments, and provide feedback, improving collaboration and reducing misunderstandings or miscommunications that could otherwise lead to additional costs.

8. Reduced Labor Costs

While automation may require some upfront investment in software and training, it can significantly reduce the need for manual drafting labor in the long run. Fewer drafting hours mean lower labor costs, leading to overall cost savings.

9. Ability to Handle Complex Designs

Automated drafting tools can efficiently handle complex millwork designs that may be challenging or time-consuming for manual drafting. This capability enables manufacturers to take on more diverse and higher-value projects without a proportional increase in design costs.

Conclusion

By leveraging automation in the Millwork Drafting services, businesses can experience greater efficiency, reduced material waste, minimized errors, and streamlined manufacturing processes. All of these factors contribute to a considerable reduction in millwork manufacturing costs, making it a competitive advantage in the market.