- Home

- About Us

- Services

- Millwork Drafting Services

- Cabinet Vision Shop Drawings

- Microvellum Shop Drawings

- CNC Machining & Support

- 3D Modeling & Rendering

- Estimation & Quantity Take Off

- Millwork Software & Support

- Millwork Contract Manufacturing

- Millwork Standards and accrediation

- A2z Millwork Certified Architecture Woodwork Institute member

- A2Z Millwork: Exemplifying Standards and Accreditation of AWMAC

- A2Z Millwork WMA (World Millwork Alliance) Standards and Accreditation

- A2z Millwork Standards and Accreditation by KCMA

- ASME Standards and Accreditation

- A2Z Millwork Certified Americans with Disabilities Act (ADA)

- A2Z Millwork Certified (NSF)Sanitation Foundation Partner

- Millwork Remote and Onsite staffing Solution

- Portfolio

- Blog

- How it Works

Staffing Solution

- Home

- Our Services

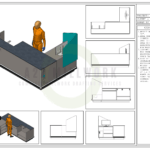

- Microvellum Shop Drawings

- Staffing Solution

Precision and accuracy are paramount in the world of Woodworking. And the Microvellum shop drawings serve as the backbone of any woodworking project, providing detailed and accurate representations of the final product. However, producing these drawings demands a skilled workforce, time, and resources. That’s where A2Z Millwork steps in with its unparalleled Microvellum Shop Drawings Staffing Solution, offering a seamless blend of expertise and efficiency.

Understand the Microvellum Shop Drawings:- Backbone of Woodworking

Microvellum shop drawings comprehensively represent woodworking projects, encompassing detailed measurements, material specifications, and assembly instructions. These drawings serve as the foundation upon which the entire woodworking process relies. Accurate shop drawings ensure that each piece fits perfectly, minimizing errors, reducing waste, and enhancing overall efficiency. They bridge the gap between design and execution, acting as the guiding force throughout the production process.

Challenges of Microvellum Shop Drawings:- Skill and Time

Producing high-quality Microvellum shop drawings is a multi-faceted task that demands both skill and time. The intricate nature of Woodworking necessitates a profound understanding of materials, measurements, and joinery techniques. Each element must be meticulously accounted for to avoid discrepancies during production. These drawings require skilled CAD technicians who can seamlessly translate design concepts into precise technical drawings.

Time is another critical factor. Developing Microvellum drawings requires careful attention to detail and a considerable investment of time. Woodworking projects are often time-sensitive, and delays in drawing production can lead to cascading delays in the entire manufacturing process. Balancing speed and precision is a complex challenge that can strain even the most capable in-house teams.

Microvellum Staffing Solution:- Elevate Your Efficiency

Recognizing the complexities of Microvellum shop drawing creation, A2Z Millwork offers a comprehensive Staffing Solution tailored specifically to meet these demands. With years of experience in the woodworking industry, A2Z Millwork understands the nuances of Microvellum software and the intricacies of woodworking processes.

Time is another critical factor. Developing Microvellum drawings requires careful attention to detail and a considerable investment of time. Woodworking projects are often time-sensitive, and delays in drawing production can lead to cascading delays in the entire manufacturing process. Balancing speed and precision is a complex challenge that can strain even the most capable in-house teams.

Expertise at Your Fingertips

A2Z Millwork's team of skilled CAD technicians brings a wealth of knowledge and experience to the table. These experts are well-versed in translating design concepts into precise Microvellum shop drawings, ensuring that every measurement, joint, and detail is accurately represented.

Time-Efficient Solutions

A2Z Millwork's staffing solution addresses the time challenge by offering a dedicated team that can quickly produce shop drawings without compromising quality. This alleviates the burden on in-house teams and allows woodworking companies to maintain their project timelines without sacrificing precision.

Cost-Effective Approach

Outsourcing Microvellum shop drawing creation to A2Z Millwork presents a cost-effective alternative to maintaining an extensive in-house CAD department. This reduces overhead costs while providing access to specialized expertise as and when needed.

Seamless Integration

A2Z Millwork seamlessly integrates with your existing workflow, ensuring a smooth transition from design to production. This collaborative approach fosters efficient communication and allows for real-time adjustments, guaranteeing that the final product aligns perfectly.

In the realm of Woodworking, Microvellum shop drawings serve as the blueprint for excellence. A2Z Millwork’s Microvellum Shop Drawings Staffing Solution empowers woodworking companies to overcome the challenges of precision, time, and resources. With a team of skilled CAD technicians, a commitment to efficiency, and a deep understanding of the woodworking industry, A2Z Millwork elevates the quality and efficiency of Microvellum drawing production. By partnering with A2Z Millwork, woodworking businesses can focus on what they do best – creating exceptional woodwork – while leaving the intricate task of Microvellum shop drawing creation in capable hands.