What is 3d Modelling

3D modelling is the process of creating a three-dimensional representation of an object or scene using specialised computer software. Under the process, a designer or artist creates a virtual object using various tools and techniques, such as polygons, curves, surfaces, and textures.

3D models can be use for various purposes, including visual effects in movies and video games, product design and prototyping, architectural visualisation, and more. 3D models can also be animated, allowing for movement and interaction with other objects in a virtual environment.

There are different types of 3D modelling techniques, including:

Polygonal Modelling:

This technique involves creating a 3D model using a series of connected polygons.

NURBS Modelling:

NURBS stands for Non-Uniform Rational B-Splines. This technique involves creating 3D models using mathematical curves and surfaces.

Sculpting:

This technique involves shaping a 3D model by digitally sculpting it like clay.

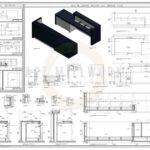

Scope of 3D Modelling in Millwork Drafting

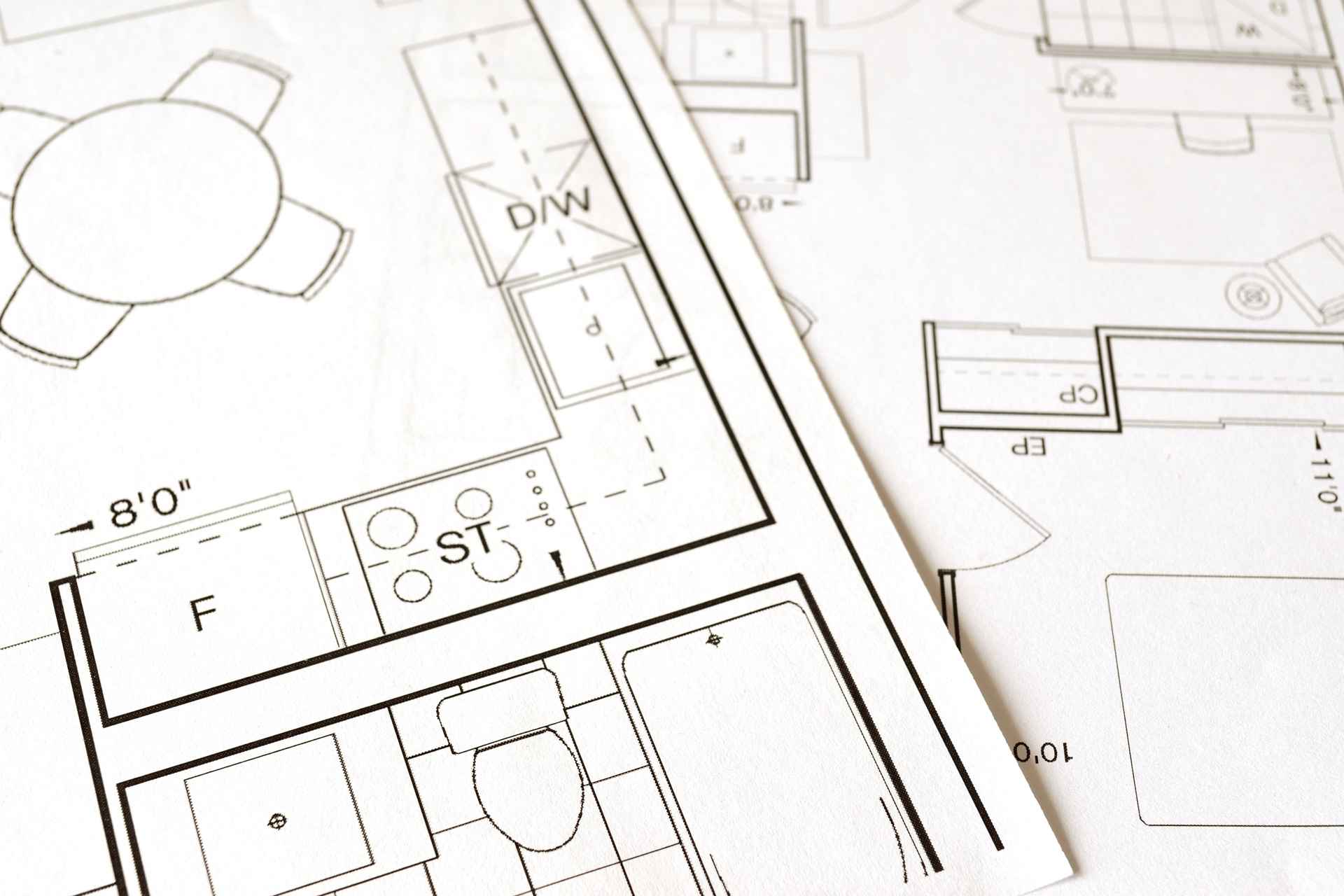

Millwork drafting has become increasingly important in the construction and woodworking industries, as it allows for creation of detailed plans and designs for custom millwork projects. One of the critical tools used in millwork drafting is 3D modelling, which offers a range of benefits over traditional 2D drafting techniques.

The scope of 3D modelling in millwork drafting is vast, allowing for the creation of highly detailed and accurate representations of millwork designs. Using specialized software, designers can create 3D models of millwork projects that allow for easy visualisation and manipulation of various design elements.

One of the primary advantages of 3D modelling in millwork drafting is its ability to facilitate better communication between designers, architects, and clients. By creating a detailed 3D model, designers can help clients better understand their design vision and make more informed decisions about the project. Additionally, 3D models can detect potential issues or conflicts early on in the design process, saving time and money in the long run.

Another advantage of 3D modelling in millwork drafting is the ability to create highly customised and intricate designs. With 3D modelling software, designers can create complex curves, angles, and other details that would be difficult or impossible to achieve with traditional drafting techniques. This level of detail can help to create truly unique and impressive millwork projects that stand out from the competition.

Key factors to consider best millwork 3D modelling services in Las Vegas

Experience and Expertise:

It’s essential to look for a service provider with experience and expertise in millwork drafting and 3D modelling. Use the latest software and technology to ensure your designs are as accurate and detailed as possible.

Customization:

Make sure the company can provide customised solutions tailored to your needs. This may include unique design elements or specific materials.

Communication:

Look for a company with excellent communication skills that keeps you informed throughout the process. This will ensure that your project is completed on time and to your satisfaction.

Reputation:

Check the company’s reputation in the industry and read reviews from previous clients. It will give you an idea of their level of expertise, professionalism, and quality of work.

Cost:

Consider the cost of the service, but don’t make it the only factor in your decision. It’s essential to find a balance between quality and affordability.

Benefits of Using 3D Modelling in Millwork Drafting

Enhanced visualisation:

3D modelling allows designers and clients to see a highly realistic, three-dimensional representation of the millwork project before it is build. It provides a better understanding of the final product’s appearance and function.

Increased accuracy:

3D modelling makes it much easier to ensure that all measurements and angles are correct, reducing the risk of errors and wasted materials.

Improved communication:

3D models can be easily shared with clients and collaborators, providing a common reference point for discussions and feedback.

Faster design process:

3D modelling tools can help designers create and modify millwork designs more quickly, saving time and resources.

More creative freedom:

3D modelling allows designers to experiment with different shapes, sizes, and materials, expanding the range of possible millwork designs.

Better cost estimates:

3D modelling tools can help estimate the cost of materials and labour more accurately, allowing for more specific project budgets.

Increased productivity:

3D modelling allows for creating detailed and complex millwork designs quickly and efficiently, improving overall productivity.

Enhanced collaboration:

3D modelling software enables designers, architects, engineers, and builders to collaborate and work together on a single platform.

Improved sustainability:

With 3D modelling, it is easier to optimise designs for sustainability, including reducing waste and using environmentally friendly materials.

Better customer satisfaction:

3D modelling helps customers visualise the final product better, leading to more accurate expectations and increased satisfaction with the finished millwork.

Conclusion-

There are many benefits to using 3D modelling in millwork drafting for woodworking designers. Its precision, efficiency, and ability to create realistic visualisations make it the USA’s best millwork 3D modelling option. This technology allows designers to improve their productivity, save money, and create customised, high-quality millwork designs.