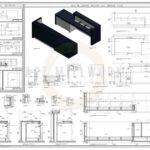

Millwork drafting is the process of creating detailed technical drawings or blueprints that specify the dimensions, materials, and construction methods for custom woodwork products such as cabinets, moldings, and staircases. Millworkers and carpenters use these drawings to fabricate and install the finished products according to the designer’s specifications.

Millwork drafting has come a long way since the early days of hand-drawn blueprints. With the advent of 3D modeling software like Solidworks, millwork shop drawings have been revolutionized, providing designers and fabricators with a powerful tool for creating complex designs with accuracy and speed. In this blog post, we’ll take a closer look at how 3D modeling has transformed the world of millwork drafting.

What are Millwork Shop Drawings?

Millwork shop drawings are detailed plans that provide a roadmap for fabricating millwork components such as cabinetry, moldings, and other custom woodwork. These drawings are created by designers, architects, or millwork drafting technicians for detailed instructions fabricators to follow, ensuring that the finished product meets the client’s specifications.

Revolutionizing Millwork Drafting with 3D Modeling

3D Modeling using Solidworks has revolutionized the millwork industry by providing designers and drafting technicians a powerful tool to create accurate and detailed shop drawings. Using software like Solidworks, designers can create complex 3D models of millwork components that can be easily modified and refined to meet the client’s needs.

The Benefits of 3D Modeling for Millwork Drafting

There are several benefits to using 3D modeling for millwork drafting:

1) Accuracy:

3D modeling software provides designers with a high degree of accuracy, allowing them to create precise and detailed shop drawings.

2) Visualization:

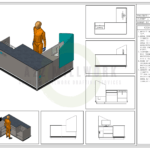

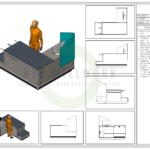

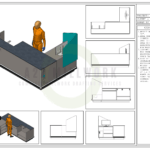

3D models provide a realistic representation of the finished product, allowing designers and clients to visualize the final result before fabrication begins.

3) Time-saving:

3D modeling software allows designers to create and modify designs quickly, reducing the time needed to create detailed shop drawings.

4) Collaboration:

3D models can be easily shared and modified, allowing for collaboration between designers, drafters, and fabricators.

How 3D Modeling Helps in Accurate Millwork Drafting

- 3D modeling is the process of creating a digital representation of a physical object or space. For example, in millwork drafting, 3D modeling is used to create a virtual representation of the custom woodwork or cabinetry that will be fabricated. This virtual representation allows designers and craftsmen to visualize the finished product in great detail and make necessary adjustments before beginning the fabrication process.

- One of the primary benefits of 3D modeling in millwork drafting is accurately capturing the intended design. With 3D modeling, designers can create a digital model of the custom woodwork or cabinetry that includes all of the necessary details and specifications. This ensures that the final product will match the designer’s vision and meet the client’s expectations.

Use of Solidworks

- Solidworks is a popular 3D modeling software used for millwork drafting. It allows designers to create detailed 3D models of millwork components, including cabinetry, moldings, and other custom woodwork. In addition, the software provides a range of tools for creating complex geometries, including fillets, chamfers, and other features.

- Solidworks also allows designers to create detailed exploded views of millwork components, making it easier for fabricators to understand how the components fit together. The software also provides tools for creating detailed shop drawings, including dimensions, annotations, and bill of materials.

- Additionally, 3D modeling allows designers to experiment with different design options and make changes quickly and easily. This is especially useful in the early stages of the design process, as it allows designers to explore different design ideas without committing to a specific approach. This can result in a more refined final design that meets the client’s needs and preferences.

- Once the 3D model has been created, it generates highly accurate millwork drafting plans and drawings. Craftsmen can use these plans and drawings to fabricate custom woodwork or cabinetry with high precision. Using 3D models as a reference, craftsmen ensure that the finished product matches the intended design and specifications.

- 3D modeling can also help to minimize errors and reduce waste in the fabrication process. By creating a digital model of the custom woodwork or cabinetry, designers and craftsmen can identify potential issues and make adjustments before any materials are cut. This can reduce the amount of material waste and save time and money in the fabrication process.

3D Modeling for Millwork Drafting: Tips and Tricks for Beginners

1) Start with a basic design:

When starting with 3D modeling, it is important to begin with a simple design. This allows beginners to understand the software and its capabilities without feeling overwhelmed. Once you become familiar with the software, you can then move on to more complex designs.

2) Learn the shortcuts:

3D modeling software comes with various shortcuts that can help you save time and improve your workflow. Take the time to learn these shortcuts and incorporate them into your modeling process.

3) Use reference images:

Using reference images can help you create accurate designs. For example, collect images of similar millwork designs or use pictures from real-life structures. This can help you to understand the proportions, materials, and details required for the design.

4) Be consistent:

Consistency is key when it comes to millwork drafting. Ensure your measurements, scale, and proportions are consistent throughout the design. Consistency will help you to create accurate models that can be easily translated into physical structures.

5) Take advantage of plugins:

3D modeling software comes with various plugins that can help you to enhance your designs. Take the time to explore these plugins and find out which ones can improve your workflow and design process.

6) Practice:

Like any skill, 3D modeling requires practice. The more you practice, the better you will become. Take the time to create different designs and experiment with various tools and techniques.

Conclusion-

3D modeling is an essential tool for achieving accuracy in millwork drafting. It allows designers and craftsmen to visualize the finished product in great detail, experiment with different design options, generate highly accurate drafting plans and drawings, minimize errors and waste in the fabrication process, and create detailed visualizations and presentations for clients. By leveraging the power of 3D modeling, designers and craftsmen can create custom woodwork and cabinetry that meets the highest standards of quality and craftsmanship.