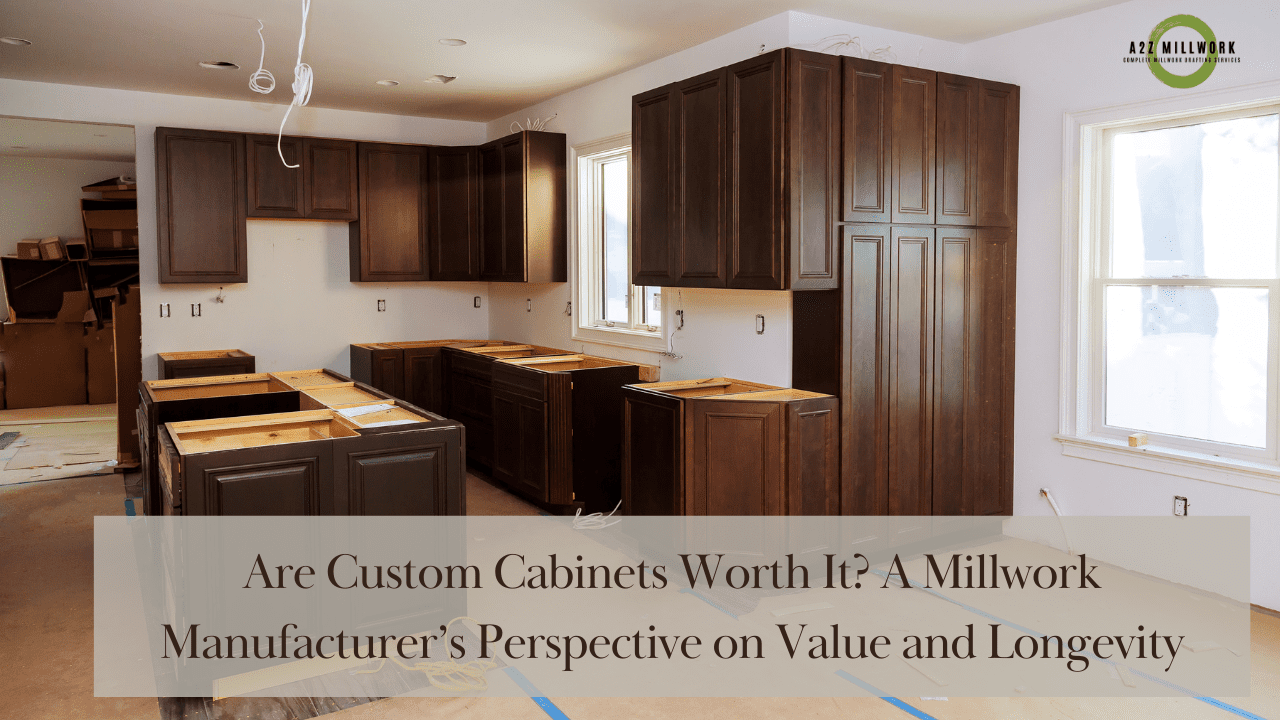

Introduction: The Custom Cabinet Debate in the U.S. Market

In the world of interior remodeling and new construction, homeowners and builders in the United States often face a crucial decision: Are custom cabinets really worth the investment? With big-box retailers offering ready-to-assemble cabinets at a fraction of the cost, it’s natural to question the value of bespoke millwork.

But when viewed from a millwork manufacturer’s perspective—considering longevity, craftsmanship, material flexibility, and how modern CNC-compatible drafting systems streamline production—the answer becomes clearer.

This article explores the true value of custom cabinets through the lens of professional millwork design and manufacturing, with insights into how today’s drafting workflows ensure quality, precision, and long-term ROI.

Understanding the Core Differences – Custom vs Stock Cabinets

What Are Custom Cabinets?

Custom cabinets are individually designed and crafted to fit the exact dimensions, style, material preferences, and functional needs of a specific space. Unlike stock cabinets, which are mass-produced in fixed sizes and styles, custom cabinets offer flexibility in:

- Wood species (oak, maple, cherry, walnut, etc.)

- Finishes and stains

- Hardware types and placement

- Interior accessories (pull-outs, dividers, lighting)

- Dimensions tailored to unique floor plans

Stock Cabinets: Pros and Trade-offs

Stock cabinets, available from national home improvement stores, are generally:

- Mass-produced in standardized sizes (typically 3-inch width increments)

- Limited in color and material options

- Faster to install and often less expensive upfront

However, they’re often made from lower-grade materials (e.g., particle board) and lack the precise fit and finish of a millwork-driven custom cabinet project.

The Real Value of Custom Cabinets in the U.S.

1. Long-Term Durability

Custom cabinets are typically built using solid wood construction, high-grade plywood boxes, and dovetail joinery, all of which significantly increase their lifespan compared to RTA (ready-to-assemble) alternatives. U.S. homeowners who opt for custom cabinetry can expect:

- Lifespans of 20–30+ years

- Fewer repairs and replacements

- Retained structural integrity under heavy daily use

2. Enhanced Property Value

According to Zillow and Houzz studies, custom kitchen cabinetry is among the top features homebuyers look for in upscale properties. Custom cabinets signal:

- Quality craftsmanship

- Thoughtful design

- Higher resale value

They are particularly favored in U.S. housing markets such as California, Texas, New York, and Florida where premium real estate often demands equally premium finishes.

3. Personalization and Functionality

Custom cabinetry accommodates how a homeowner actually lives. Whether it’s a built-in spice drawer, hidden pantry door, or adjustable shelving for appliance storage, every feature is tailored. In contrast, stock cabinets often require workarounds or space sacrifices.

How Millwork Manufacturers Optimize Custom Cabinet Production

Leveraging Drafting Standards for Precision

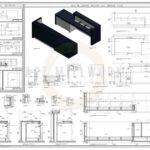

Modern millwork manufacturers no longer rely on hand-drawn plans or inconsistent designs. Instead, they use CAD-based drafting platforms like AutoCAD, Cabinet Vision, or Microvellum to:

- Generate 2D and 3D visualizations

- Ensure accurate measurements and tolerances

- Standardize joinery and construction details

Aligning Drafting Workflows with CNC Machinery Capabilities

One of the biggest advancements in custom cabinetry today is how drafting software integrates directly with CNC (Computer Numerical Control) machinery. When the drafting files are optimized using pre-set templates, materials, and part labeling conventions, they can be exported directly to CNC machines for:

- Precision cutting

- Automated drilling

- Edge banding

- Slotting and joinery machining

This integration minimizes human error, reduces material waste, and dramatically improves efficiency. For U.S.-based woodshops where labor is costly, CNC-aligned drafting workflows offer scalability and repeatable quality, even in one-off custom builds.

Topic Cluster 5: Sustainability and Environmental Responsibility

Many custom millwork shops in the U.S. offer FSC-certified wood, low-VOC finishes, and sustainably harvested materials. Stock cabinets often don’t provide the same level of transparency or environmental compliance.

Moreover, CNC-driven production aligned with optimized nesting strategies reduces material waste by maximizing sheet usage, another win for eco-conscious homeowners and builders.

Conclusion: Are Custom Cabinets Worth It?

From a millwork manufacturer’s perspective, the answer is a resounding yes. While the upfront cost of custom cabinetry is higher, its long-term benefits—durability, property value, and personal satisfaction—far outweigh the savings of stock solutions.

When custom cabinets are produced using standardized drafting templates and CNC-integrated workflows, the results are not only visually impressive but also mechanically precise and cost-effective over the product’s lifetime.

Why A2Z Millwork Design LLC Is the Smart Choice for Custom Cabinet Drafting

At A2Z Millwork Design LLC, we specialize in providing detailed custom cabinet drafting services tailored for the U.S. market. Our drafting experts utilize AutoCAD, Microvellum, and Cabinet Vision to create millwork drawings that are not only beautiful and code-compliant, but also CNC-ready for seamless manufacturing.

We help custom cabinet manufacturers ensure:

- Drafting consistency using AutoCAD templates

- Alignment with CNC production lines

- AWI-compliant detailing

- Reduced rework and faster shop floor output

Whether you’re building for luxury homes, hospitality, or commercial interiors, A2Z Millwork Design LLC delivers precision-driven, value-focused drafting that supports the true worth of custom cabinetry.