Introduction: The Drafting Revolution in U.S. Casework Manufacturing

The U.S. casework manufacturers industry is undergoing a technological shift. Precision, scalability, and customization have become critical requirements in modern cabinetry and millwork. This shift is largely due to changing client expectations, growing demand for smart manufacturing, and the pressure to deliver faster, more accurately. At the center of this transformation is one name that’s rapidly gaining momentum — Cabinet Vision.

Cabinet Vision, a powerful software solution designed for cabinet and casework professionals, is redefining how drafting is done in the United States. In this article, we dive into why U.S. casework manufacturers are switching to Cabinet Vision for drafting precision, how it compares with other drafting tools, and the strategic benefits it offers to both small shops and large production facilities.

Understanding Drafting Precision in Casework Manufacturing

What is Drafting Precision in Casework?

Drafting precision refers to the accuracy and level of detail in technical shop drawings and specifications used to fabricate custom casework. Inaccurate drafting can lead to material waste, delays in production, and rework costs. With the push towards digital transformation, manufacturers are now seeking tools that deliver extremely detailed and fabrication-ready outputs.

Why Precision is Non-Negotiable

- Customization Needs: U.S. clients increasingly demand unique sizes, finishes, and styles.

- Lean Manufacturing: Precise drawings enable optimization of material usage and reduce scrap.

- Compliance Requirements: Projects must adhere to local and national standards (e.g., AWI or LEED).

- Integration with CNC Machines: Accurate drafting ensures seamless integration with automated manufacturing processes.

Why Cabinet Vision is the Tool of Choice in 2025

Cabinet Vision: A Brief Overview

Cabinet Vision is an advanced CAD/CAM software built specifically for woodworkers, casework shops, and cabinet makers. It allows users to design, visualize, and manufacture custom cabinets and casework with a high degree of accuracy.

Key Features Driving Adoption in the USA

- Parametric Design Flexibility

- Modify cabinets by changing parameters (e.g., height, depth, material) instantly.

- Easily create and reuse templates for repetitive design tasks.

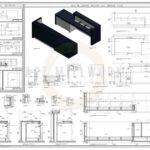

- Advanced Section Views and Joinery Detailing

- Show internal joinery techniques such as dowels, dados, or dovetails.

- Produce fully annotated section views for clear shop communication.

- CNC Integration and Nesting Optimization

- Output G-code compatible with most CNC routers used in U.S. shops.

- Automated nesting reduces waste and boosts material efficiency.

- Reporting and Cost Estimation

- Built-in costing reports, materials lists, and cutlists.

- Helps project managers provide accurate bids and reduce overages.

- Scalability for Shops of All Sizes

- Cabinet Vision is used by both small cabinet makers and large architectural millwork firms.

- Scalable component libraries and modular add-ons make it adaptable.

Market Demand in the USA for Cabinet Vision

Current U.S. Market Landscape

- According to IBISWorld, the U.S. cabinet and vanity manufacturing market was valued at $17.9 billion in 2024 and continues to grow steadily.

- High-end residential, hospitality, and commercial sectors are major drivers for custom casework.

- Automation and digital fabrication have become essential for staying competitive in these sectors.

Why Manufacturers Are Switching

- Labor Shortages: Skilled drafters are hard to find. Cabinet Vision reduces dependency on manual drafting.

- Fast Turnarounds: Time-to-market is critical. Automated workflows speed up production.

- Increased Complexity: Jobs now include complex joinery, specialty materials, and LEED requirements.

- Cloud-Based Collaboration: Cabinet Vision integrates easily with project management tools, making remote work and subcontractor collaboration easier.

Real-World Use Cases of Cabinet Vision in Casework Manufacturing

Residential Projects

- Creating fully customized kitchen and bath cabinetry with accurate 3D visualizations.

- Generating shop-ready drawings for seamless communication between designers and builders.

Commercial Interiors

- Producing modular office and retail displays with adjustable component libraries.

- Quickly modifying designs to suit franchise specifications or branding guidelines.

Institutional Casework (Schools, Labs, Hospitals)

- Cabinet Vision allows easy compliance with institutional safety standards.

- Accuracy ensures error-free installations in high-precision environments.

Millwork Subcontractors

- Firms acting as subcontractors can use Cabinet Vision to submit precise, approved shop drawings for architect review.

- Boosts confidence and improves approval turnaround.

Building a Custom Component Library for Long-Term Scalability

Many U.S. casework firms are future-proofing their business by creating custom component libraries in Cabinet Vision.

Benefits:

- Standardized casework styles

- Faster drafting turnaround for repeat clients

- Easier onboarding of new drafters

- Scalable across multiple locations or franchises

This shift toward scalable drafting systems gives U.S. manufacturers an edge in terms of speed, accuracy, and repeatability.

Conclusion: A2Z Millwork Design LLC – Your Cabinet Vision Drafting Experts in the U.S.

At the forefront of this technological shift is A2Z Millwork Design LLC, a leading provider of millwork drafting and Cabinet Vision shop drawing services in the United States.

Why Choose A2Z Millwork Design LLC?

- Cabinet Vision Specialists: With a team of experienced drafters, we produce accurate, code-compliant casework drawings.

- Speed & Precision: Our workflows are optimized using the latest Cabinet Vision capabilities for faster turnaround.

- Custom Component Libraries: We help clients build scalable drafting systems tailored to their business.

- Client-Centric Approach: We collaborate closely with manufacturers, contractors, and architects to ensure design intent is always preserved.

Our Services Include:

- Casework Shop Drawings

- Cabinet Vision 3D Drafting

- Section Views & Joinery Detailing

- Nesting Optimization Reports

- CNC-Ready Output

As more U.S. casework manufacturers make the switch to Cabinet Vision for drafting precision, partnering with a trusted expert like A2Z Millwork Design LLC ensures you stay ahead of the curve.

Get in touch today to elevate your drafting processes and deliver world-class millwork with accuracy, speed, and confidence.