Introduction

The millwork industry is undergoing a transformation, driven by the adoption of smart automation. Traditional shop drawing processes, which were once time-consuming and prone to human error, are now becoming more efficient with the integration of automation technologies. By leveraging advanced software tools, manufacturers can streamline workflows, enhance precision, and significantly reduce production time. In fact, smart automation in millwork shop drawings can cut production time by up to 30%, improving efficiency and reducing costs.

This article explores how automation is reshaping millwork drafting, the benefits it offers, and how businesses in the U.S. market can leverage these advancements to stay competitive. We will also highlight the role of A2Z Millwork Design LLC, a leading provider of millwork shop drawings, in implementing these technologies.

The Role of Smart Automation in Millwork Shop Drawings

1. Understanding Smart Automation in Millwork

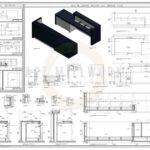

Smart automation in millwork shop drawings involves the use of computer-aided design (CAD) software, parametric modeling, artificial intelligence (AI), and machine learning (ML) to create highly accurate and optimized designs. These technologies eliminate manual drafting errors, ensure design consistency, and accelerate the entire production process.

Key technologies driving automation in millwork shop drawings include:

- Cabinet Vision & Microvellum – Industry-leading software tools that automate the generation of shop drawings.

- AI-driven Parametric Modeling – Enables dynamic adjustments to designs without redrawing components manually.

- Nesting Optimization Software – Reduces material waste and optimizes cutting layouts.

- BIM (Building Information Modeling) – Facilitates collaboration between architects, designers, and fabricators.

By automating repetitive tasks, manufacturers can focus on refining designs and improving overall production quality.

How Smart Automation Reduces Production Time by 30%

2. Eliminating Manual Drafting Errors

One of the biggest challenges in traditional millwork shop drawings is human error. Manually creating detailed millwork plans can be time-consuming and susceptible to miscalculations. Even minor mistakes can lead to costly rework, project delays, and material wastage. Automation eliminates these errors by implementing AI-driven accuracy checks, rule-based design generation, and real-time error detection.

For example, parametric modeling ensures that any modification in a design automatically updates all related components, reducing the need for manual revisions. This speeds up the approval process and helps projects move forward faster.

3. Optimized Nesting for Material Efficiency

Material wastage is a significant concern in millwork production. Smart automation tools, such as nesting optimization software, maximize material utilization and minimize waste. This technology determines the most efficient way to cut materials, reducing offcuts and saving money on raw materials.

According to industry reports, automated nesting solutions can cut production waste by up to 15% and significantly lower costs. This also contributes to a faster production cycle, as fewer material adjustments and corrections are needed.

4. Seamless Collaboration with BIM Integration

Building Information Modeling (BIM) plays a crucial role in collaborative design and construction processes. By integrating millwork shop drawings with BIM, designers, architects, and manufacturers can work on a single shared model. This eliminates communication gaps, reduces back-and-forth revisions, and speeds up project timelines.

Benefits of BIM in millwork drafting include:

- Real-time design updates shared across teams.

- Enhanced visualization of millwork components within a project.

- Fewer RFIs (Requests for Information) and fewer change orders.

- Faster approval processes.

By reducing project misalignment and enhancing coordination, BIM helps businesses complete millwork projects more efficiently.

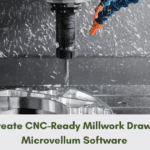

5. Faster CNC Machine Integration

Computer Numerical Control (CNC) machines are a game-changer in millwork production. Automating shop drawings means that CNC files can be generated instantly, reducing lead times for fabrication. Traditional methods require manual conversion of shop drawings into CNC-compatible files, which can lead to inefficiencies and potential errors.

With automation, CNC-ready drawings are created in real time, allowing for immediate production without manual input. This means faster turnaround times, higher production capacity, and improved overall efficiency.

Key Benefits of Smart Automation in Millwork Shop Drawings

- Increased Accuracy – Automation eliminates human errors and ensures precision in measurements and design details.

- Reduced Labor Costs – Fewer manual tasks mean reduced dependency on highly skilled labor, leading to cost savings.

- Faster Approvals – Automated workflows streamline the approval process, reducing design bottlenecks.

- Enhanced Productivity – Manufacturers can handle more projects with the same resources, increasing profitability.

- Sustainability and Waste Reduction – Optimized material usage leads to environmentally friendly manufacturing practices.

These benefits make smart automation an essential investment for millwork manufacturers looking to stay competitive in the U.S. market.

The Future of Millwork Shop Drawings: Smart Automation Trends

1. AI-Powered Design Enhancements

The future of millwork shop drawings is driven by artificial intelligence (AI). AI can analyze design parameters, suggest optimizations, and even predict potential design flaws before they occur.

2. Cloud-Based Collaboration

Cloud-based platforms allow real-time collaboration between stakeholders, ensuring all changes are tracked, and version control is maintained seamlessly.

3. Augmented Reality (AR) & Virtual Reality (VR)

AR/VR integration will enable designers and clients to visualize millwork designs in a 3D immersive environment, improving decision-making and client satisfaction.

Conclusion: How A2Z Millwork Design LLC is Leading the Way

The millwork industry is rapidly evolving, and businesses that adopt smart automation will have a competitive edge in the U.S. market. With the ability to cut production time by 30%, improve accuracy, and optimize material usage, automation is no longer an option but a necessity.

A2Z Millwork Design LLC is at the forefront of this technological revolution. By leveraging Cabinet Vision, Microvellum, BIM integration, and advanced nesting optimization, A2Z Millwork Design delivers highly accurate, automated millwork shop drawings that enhance production efficiency and reduce costs for clients.

If you’re looking to transform your millwork drafting process and stay ahead in the industry, partner with A2Z Millwork Design LLC. Their expertise in automation ensures that your projects are delivered on time, with precision and cost efficiency.

Get in Touch with A2Z Millwork Design LLC Today!

Visit A2Z Millwork Design LLC to learn more about how automation can enhance your millwork shop drawings and production processes.

Final Thoughts

Smart automation is redefining the millwork industry by streamlining workflows, improving accuracy, and reducing production time by up to 30%. Companies that invest in these technologies will not only improve operational efficiency but also gain a significant competitive advantage in the U.S. market. Are you ready to embrace the future of millwork drafting?