The integration of 3D modeling using SolidWorks has been a game changer for the custom millwork industry. As clients demand more complex and unique woodworking solutions, millwork professionals in the USA have adopted 3D modeling technology to provide accurate, detailed, and efficient designs. SolidWorks, a powerful software widely used in mechanical engineering, has found a new purpose in millwork. It enables millwork designers and manufacturers to create intricate 3D models, ensuring precision and minimizing costly errors. This article explores how 3D modeling in SolidWorks transforms custom millwork design, with a focus on the U.S. market.

The Rise of Custom Millwork Design in the USA

Custom millwork refers to the specialized creation of wood-based architectural elements such as cabinets, moldings, and furniture. Unlike standard production, custom millwork caters to unique, one-of-a-kind designs tailored to individual preferences or architectural specifications. Over the past decade, there has been a steady rise in demand for custom millwork across high-end residential and commercial projects in the United States.

The increasing popularity of 3D modeling in SolidWorks has enabled millwork designers to innovate in ways that were previously impossible. SolidWorks enhances design quality, reduces production time, and eliminates many risks associated with traditional drafting techniques.

Why SolidWorks for Millwork?

SolidWorks is a comprehensive 3D computer-aided design (CAD) and computer-aided engineering (CAE) software known for its user-friendly interface and powerful capabilities. For the millwork industry, which requires precision and flexibility, SolidWorks offers several advantages:

- Accurate 3D Visualization

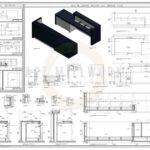

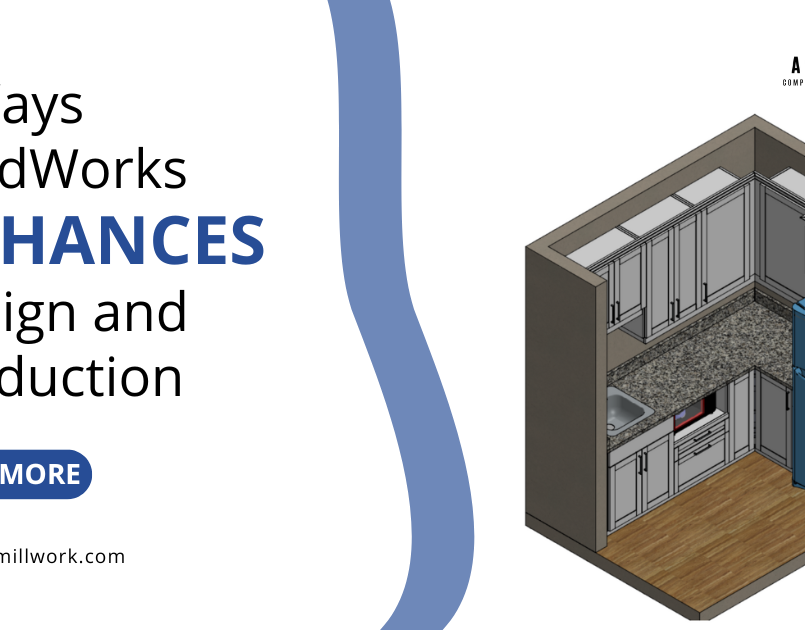

One of the primary reasons custom millwork professionals choose SolidWorks is its ability to create highly detailed and accurate 3D visualizations. By modeling designs in three dimensions, millwork designers can clearly communicate their vision to clients, contractors, and manufacturers. This accuracy is crucial for ensuring that every custom detail is executed precisely, from complex moldings to ornate cabinetry. - Improved Design Collaboration

SolidWorks facilitates seamless collaboration among different stakeholders in a millwork project, such as architects, interior designers, and contractors. This software allows everyone to visualize the final product and provide feedback before production begins. As custom millwork projects often involve a variety of complex elements, the ability to collaborate effectively using 3D models reduces misunderstandings and miscommunication. - Parametric Modeling

One of the standout features of SolidWorks is its parametric modeling capabilities. This feature allows millwork designers to establish relationships between different components in a model. For example, changing the dimensions of one part automatically updates related parts, ensuring design consistency. Parametric modeling streamlines the design process, enabling millwork professionals to respond quickly to changes in client preferences or project requirements. - Material and Texture Simulation

Another significant benefit of using SolidWorks for millwork design is its ability to simulate different materials and textures. Designers can apply wood grains, stains, and finishes to 3D models, giving clients a realistic preview of their custom pieces. This level of detail helps customers make informed decisions about the final appearance of their millwork, while also helping manufacturers plan for material procurement. - Efficient Prototyping and Testing

SolidWorks allows millwork designers to create virtual prototypes, which can be tested for functionality and fit before physical production begins. This saves time and reduces the costs associated with creating physical prototypes. Moreover, by identifying potential issues early in the design process, millwork professionals can avoid costly mistakes that might occur during production.

The Impact of 3D Modeling in Millwork Production

The use of 3D modeling through SolidWorks has had a profound impact on the efficiency, precision, and creativity of custom millwork production. Here are some key ways in which 3D modeling has transformed the industry:

1. Reduced Design Errors and Revisions

In traditional 2D drafting, errors can easily arise from misinterpretations or discrepancies in scale and proportions. However, 3D modeling in SolidWorks provide a clear and detailed representation of the final product, minimizing the potential for errors. SolidWorks allows millwork professionals to inspect every angle of a design, ensuring that all components fit together seamlessly. This accuracy reduces the number of design revisions required, saving both time and money.

2. Streamlined Workflow and Shorter Lead Times

SolidWorks simplifies the workflow by integrating design, analysis, and manufacturing processes. The software allows designers to create highly detailed models that can be directly used for CNC programming, minimizing the time required to translate design files into manufacturing instructions. As a result, lead times are shortened, and projects can be completed more efficiently.

3. Customization and Flexibility

Custom millwork projects require a high degree of flexibility to accommodate the unique preferences of clients. SolidWorks’ parametric modeling and real-time editing features allow designers to quickly make adjustments without starting from scratch. This flexibility ensures that millwork professionals can meet the demands of even the most complex custom projects, enhancing client satisfaction.

4. Enhanced Client Communication and Satisfaction

One of the significant challenges in custom millwork projects is helping clients visualize the final product before production begins. With SolidWorks, designers can create photorealistic 3D renderings

give clients a clear idea of how the finished millwork will look in their space. This visual clarity improves communication between designers and clients, leading to higher satisfaction levels and fewer changes during production.

5. Sustainability and Waste Reduction

By creating accurate 3D models, SolidWorks helps millwork professionals optimize their designs for material efficiency. The software allows designers to simulate different cutting patterns and nesting strategies to minimize waste during production. This approach not only reduces material costs but also supports sustainability efforts by reducing the environmental impact of millwork production.

The Future of Millwork with SolidWorks

The adoption of 3D modeling software like SolidWorks is expected to continue growing in the millwork industry. As clients demand more customization and precision, millwork professionals in the USA will increasingly rely on advanced technology to meet these expectations. Furthermore, the rise of Building Information Modeling (BIM) in the construction industry has created a need for millwork professionals to integrate their designs into larger architectural projects seamlessly.

SolidWorks is well-positioned to play a significant role in the future of millwork, offering powerful tools that enhance design quality, improve collaboration, and streamline production. With its ability to crekate detailed, accurate, and customizable 3D models, SolidWorks is set to become an essential tool for millwork professionals aiming to stay competitive in the custom woodworking market.

Conclusion

In conclusion, 3D modeling in SolidWorks is transforming the way custom millwork designs are created, communicated, and manufactured. Its ability to enhance accuracy, streamline workflows, and improve client satisfaction makes it a valuable tool for millwork professionals in the USA. As the demand for custom woodworking continues to rise, companies like A2Z Millwork Design LLC are at the forefront of this technological shift. By leveraging SolidWorks, A2Z Millwork Design provides detailed and accurate 3D modeling services that ensure the success of custom millwork projects. For those seeking precision, efficiency, and creativity in their millwork designs, SolidWorks is the future, and A2Z Millwork Design is leading the way in the United States.