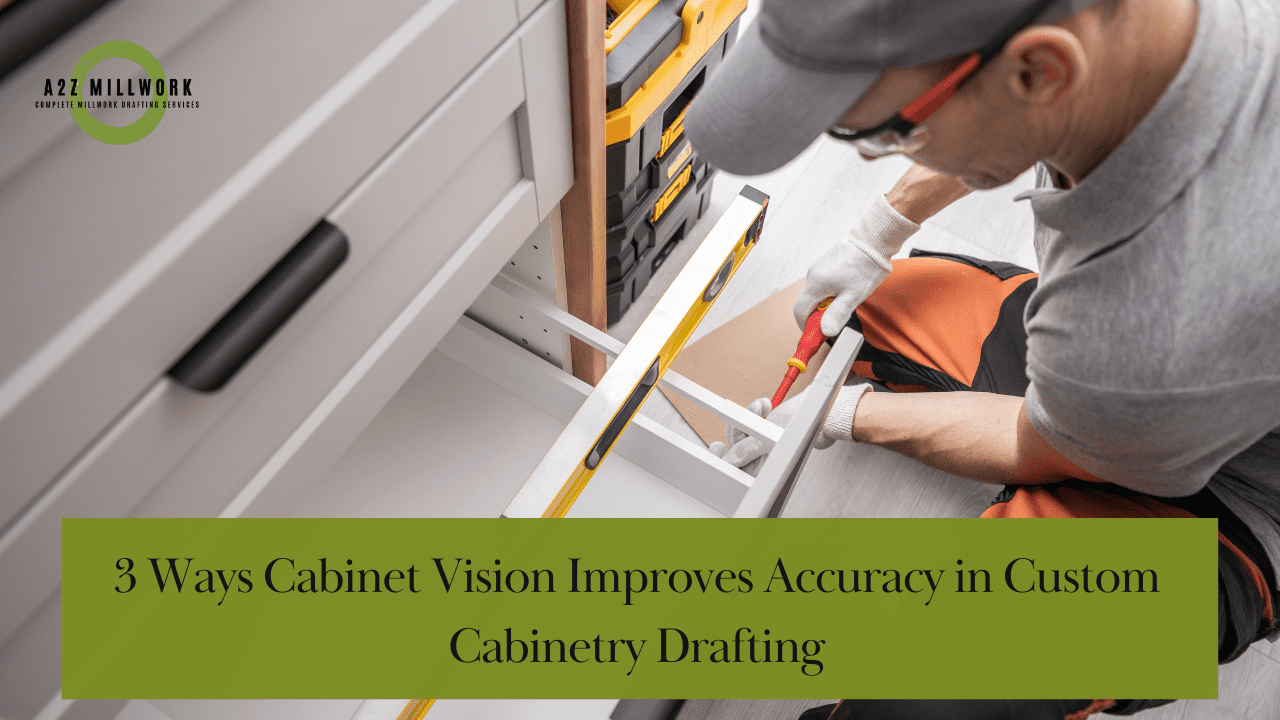

In the fast-paced world of custom cabinetry manufacturing, accuracy is not just a metric—it’s a mandate. For U.S. woodworking professionals, every miscalculation or drafting error can translate into costly material waste, production delays, or dissatisfied clients. In this context, Cabinet Vision has emerged as a vital software tool that enables unparalleled precision in cabinetry design and drafting.

This article explores three core ways Cabinet Vision improves drafting accuracy for custom cabinetry projects. Drawing from industry standards, real-world practices, and the needs of the U.S. market, we explain why this software has become essential for manufacturers seeking to stay competitive in 2025 and beyond.

The U.S. Cabinetry Industry and the Need for Precision

A Market That Demands Detail

The U.S. cabinetry market is expected to surpass $25 billion by 2026, driven by both residential renovations and commercial build-outs. As demand for custom solutions grows, clients—from homeowners to architects—expect:

- Flawless fit and finish

- Seamless installations

- Aesthetic cohesion with the rest of the interior design

Achieving these expectations starts with accurate drafting. That’s where Cabinet Vision steps in.

What Is Cabinet Vision?

Cabinet Vision is an advanced CAD/CAM software designed specifically for cabinet and casework manufacturers. It integrates 3D design, part optimization, CNC programming, and material tracking into a single, seamless workflow.

From drafting detailed elevation views to nesting parts for CNC routers, the platform is engineered to reduce human error and maximize efficiency across custom cabinetry operations.

How Cabinet Vision Improves Drafting Accuracy

1. Parametric Design and Real-Time 3D Visualization

One of the most transformative features of Cabinet Vision is its parametric design capability. Designers and drafters can input measurements, materials, and hardware preferences that automatically adjust the geometry of components in real time.

Benefits to U.S. Manufacturers:

- Immediate feedback: See exactly how a change in dimensions affects other components.

- Real-time clash detection: Prevents issues like overlapping parts or misaligned hardware.

- Better client collaboration: Clients can preview 3D renderings and request changes before production.

This results in fewer revision cycles and dramatically increases drafting accuracy from the outset.

2. Automated Cut Lists and Part Labeling

Manual drafting can introduce inconsistencies in part labeling, dimensions, or materials. Cabinet Vision eliminates this by generating automated cut lists directly from the 3D model. Each part is labeled and nested with corresponding material information.

Benefits to U.S. Manufacturers:

- Fewer errors in production: Machine-readable outputs reduce manual transcription errors.

- Efficient material usage: Minimizes waste by optimizing nesting patterns.

- Consistent labeling: Ensures that shop floor teams know exactly what to fabricate.

This automated pipeline strengthens the link between design and fabrication, ensuring that what is drafted is what gets built.

3. DXF-to-CNC Integration for Seamless Fabrication

Cabinet Vision’s powerful DXF-to-CNC integration means that once a design is finalized, it can be sent directly to CNC machinery without additional programming.

Benefits to U.S. Manufacturers:

- Reduces setup time: Eliminates the need for manual G-code writing.

- Improves consistency: CNC machines receive instructions that are identical to the draft.

- Scalable operations: Enables high-volume, custom output with reduced risk of error.

Especially for U.S. firms managing multiple projects across commercial and residential sectors, this integration offers a significant competitive advantage.

Topic Cluster 3: Use Cases and Industry Applications

Residential Cabinetry

Whether it’s a custom kitchen remodel in New York or a built-in media wall in Los Angeles, precision is non-negotiable. Cabinet Vision helps streamline:

- Frameless or face-frame construction

- Accurate door and drawer sizing

- Integration of custom inserts and accessories

Commercial Casework

In institutional settings like schools, hospitals, and offices, speed and code compliance are critical. Cabinet Vision aids in:

- ADA-compliant layouts

- Fire-retardant material tracking

- Standardized production for repeated units

Multi-Family Housing Projects

For large-scale developments, consistency is key. Cabinet Vision supports:

- Batch processing of floorplans

- Template-based drafting for rapid revisions

- Bulk CNC data export

Why Accuracy Reduces Cost and Increases Client Trust

Accuracy isn’t just about quality control; it’s a direct path to:

- Lower rework costs

- On-time delivery

- Higher client satisfaction and referrals

According to a recent survey of U.S. millwork manufacturers, firms that adopted automated drafting systems like Cabinet Vision saw a 30% reduction in production delays due to drawing errors.

Conclusion: A2Z Millwork Design LLC Delivers Drafting Excellence with Cabinet Vision

A2Z Millwork Design LLC is a U.S.-based leader in custom millwork drafting solutions. As specialists in Cabinet Vision shop drawings, they help cabinetry manufacturers across the country streamline drafting, reduce rework, and deliver high-precision results.

By leveraging Cabinet Vision’s advanced features, A2Z Millwork Design LLC ensures:

- Accurate elevation and section views

- DXF-to-CNC ready files

- Material-optimized cut lists

- Compliance with U.S. codes and industry standards

For custom cabinetry manufacturers aiming to elevate their operations in 2025 and beyond, partnering with a drafting expert like A2Z Millwork Design LLC is not just a choice—it’s a strategic advantage.

Looking to improve drafting accuracy and reduce fabrication headaches?

Contact A2Z Millwork Design LLC today to learn how their Cabinet Vision drafting services can transform your production process.

Great blog! Do you have any helpful hints for aspiring writers? I’m hoping to start my own site soon but I’m a little lost on everything. Would you propose starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m completely overwhelmed .. Any ideas? Thanks!